4.3.1.

OUTLOOK: PROGRAMMABLE FLOW CHROMATOGRAPHY

Jarda Ruzicka, Petr Chocholous and Graham Marshall

Flow Programming

Performance of flow-based analytical techniques is enhanced by miniaturization and by flow programming. Chromatography and Flow Injection, originally based on the concept of forward continuously flowing stream, are now carried out by microfluidic manipulations that comprise forward, reversed , accelerated and stopped flow. This evolution begun with invention of Sequential Injection Analysis (SIA) (Ruzicka and Marshall 1990) performed on a platform comprising a syringe pump, holding coil, multiposition valve and a flow cell. (2.1.1.). Next a chromatographic column was integrated into the SI manifold – resulting in invention of Sequential injection Chromatography (SIC) that introduced for the first time flow programming into chromatography . (D. Šatínský, P. Solich, P. Chocholouš, R. Karlícek 2003) Starting with conventional syringe and short monolithic column (4.1.6.) the proof of concept was established and comparison with the conventional LC was made along with innovative use of new column materials (4.1.8.). It is now accepted that SIC combines the advantages of multicomponent assay with the automated solution handling enhanced by versatility lent by flow programming. The combination of a selection valve with programmable flow gives the SIC technique an unprecedented flexibility in choice of injected volumes, of elution gradients and stationary phases. There are, however, several shortcoming of SI concept, inherent in design of a single pump- single line manifold, within which sample and reagent zones are sequentially stacked. As the stack flows into the holding coil, the central streamline moves at a flowrate twice as fast as flow mean velocity, which causes centerline of adjacent zones to penetrate each other. The result is series of concentration gradients of sample with reagents, that partially overlap each other. (2.2.6.C.) Therefore it is difficult to optimize reaction conditions, to use more than two reagents and to process large sample volumes, because adjacent reagents will not penetrate into the middle of a long sample zone.

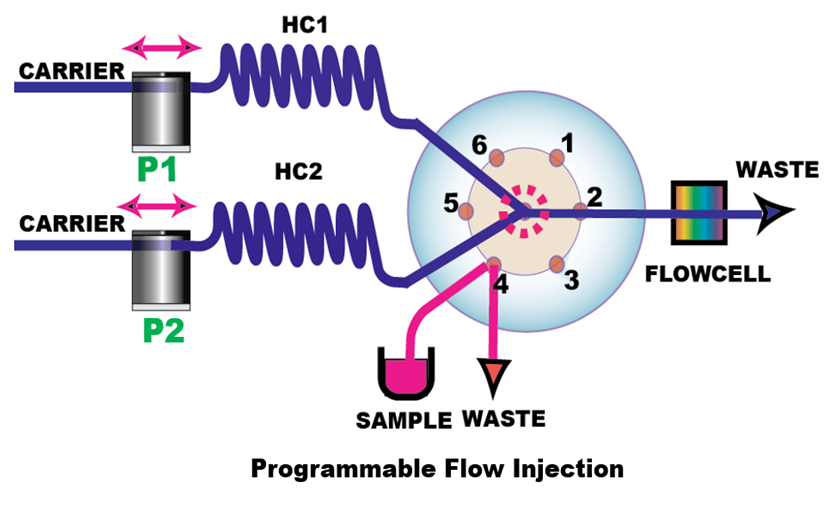

Programmable Flow Injection.

The key feature of all Flow Injection manifolds is the confluence point, where sample zone merges with reagent in the ratio determined by flow rates of merging streams. Therefore sample volume is no longer limited, because regents are merged with sample zone through its entire length, and optimization of assay protocol is simplified because sample/reagent ratio is determined by flowrates of merging streams. In pFI mode the flow of merging streams is programmed to move the sample zone forth and back between holding coils (HC1,HC2), through the same confluence point (red circle).

To exploit these advantages, all what was needed was to add a second pump to Sequential Injection manifold and connect it to central port of the multiposition valve, which will serve as a confluence point. In the (pFI) mode, deionized water is used as a carrier, reagents are added to sample zone via ports 6,5 and 3., while port 2 leads to flow cell and port 1 to waste (Ruzicka 2018). Feasibility of pFI method has been verified ). (1.2.21.) and the method was applied to automate numerous reagent based assays, to determine molar absorptivities (1.5.4.) dissociation constant, (1.5.5.) and to explore kinetics of formation of phosphomolybdenum blue (1.5.9.) and Selected Publications.